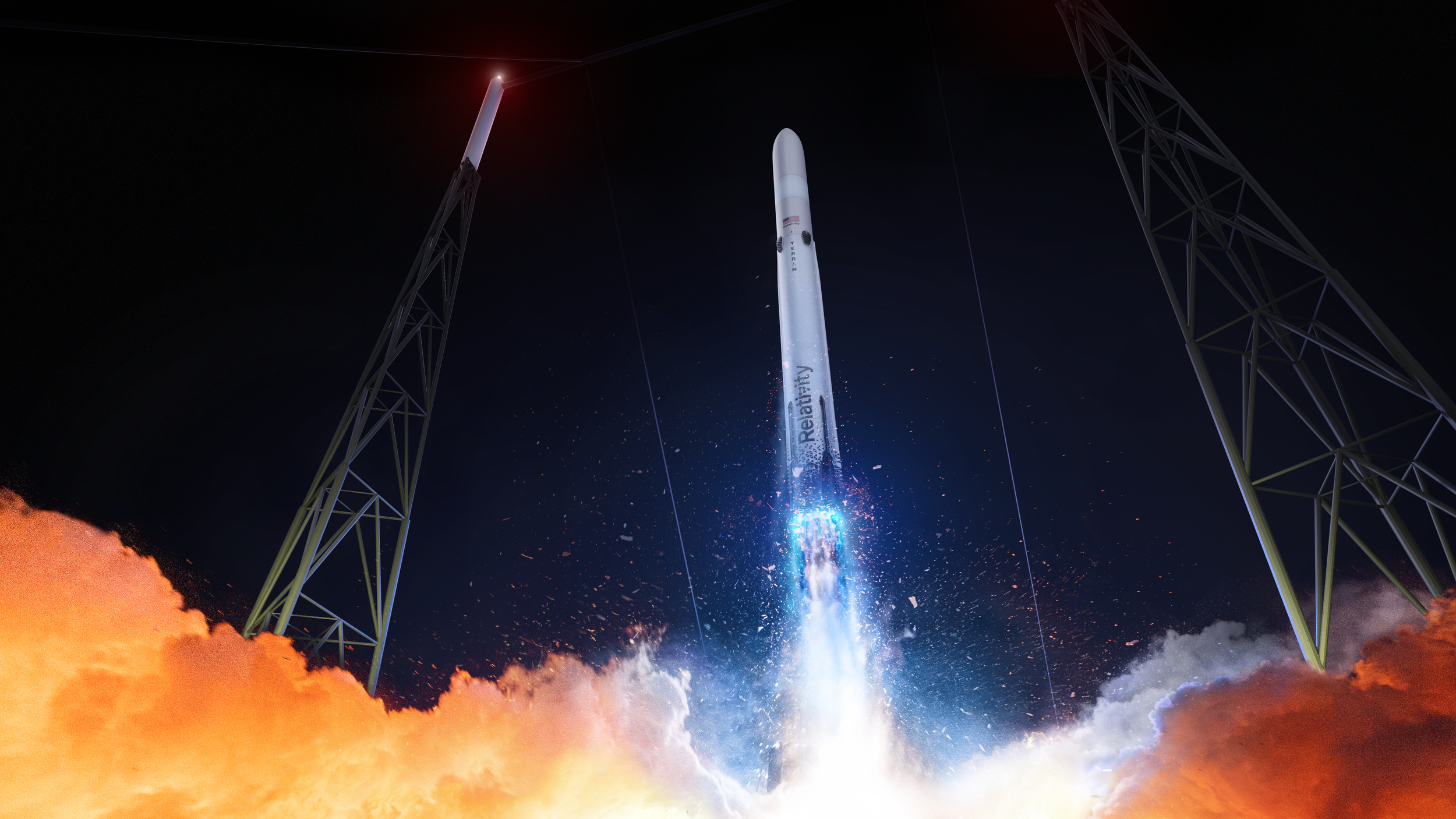

Invent the Future

Careers at Relativity

Join us on our journey to make a lasting impact, here on Earth and on Mars, as we redefine what is possible. At Relativity Space, our team is made up of bold, innovative, and collaborative individuals. We celebrate those who challenge the status quo and fearlessly pursue ambitious goals. We value diversity in all its forms, as we believe that it fuels creativity and enables us to build a more robust and inclusive future. Together, we aim to set the standard for excellence in aerospace.

Meet Our Teams

Our Values

Audacity

Challenge convention in pursuit of an expansive future.

Relentlessness

Focus on achieving intentionally meaningful results.

Humanity

Expand possibilities for the human experience in this world – and beyond.

Wonder

Approach the world with awe and a deep desire to create.

Our Community

We celebrate all the diversity and individuality that makes the human experience so beautiful. We strive to create a work environment where all people can flourish – regardless of age, gender, race, religion, or background. If you bring talent, motivation, and focus we will make sure you have a seat at the table as we invent the future together.

We offer a number of opportunities to find your community at Relativity with Employee Resource Groups (ERGs), which foster safe and inclusive spaces to connect over shared experiences and interests.

Our Locations

As a partner of NASA’s Stennis Space Center and the U.S. Space Force, Relativity operates multiple production, test, and launch sites across the country. Whether you want to work at our headquarters in California, our testing facilities in Mississippi, or our launch complex in Florida, Relativity has a spot for you.

Benefits

We are committed to our team member’s health, well-being, and growth.

COMPREHENSIVE BENEFIT PACKAGE

We offer high-quality care plans for health, dental, and vision, and provide an additional stipend for employee wellness.

COMPETITIVE COMPENSATION

In addition to receiving a competitive salary and 401(k), team members are eligible to receive equity.

WORK / LIFE INTEGRATION

We observe 11 company holidays and have a generous PTO policy.

TEAM CAMARADERIE

Our team connects and recharges with monthly lunches, game nights, holiday celebrations, and offsite events.

Parental Leave and Family Building

We offer generous parental leave and provide a $10,000 stipend for fertility, adoption, and other family-building benefits.

LEARNING AND DEVELOPMENT

Our annual learning stipend allows you to develop your professional skills and accelerate your career. We also have constant training opportunities, company Lunch and Learns, and access to industry conferences.

Student Opportunities

We are seeking exceptional students to join our team and make a lasting impact.

At Relativity, you won't just be an intern; you’ll be an integral part of the team that is redefining the realm of possibility. We understand the importance of practical learning that goes beyond the confines of the classroom. Our programs for undergraduate and graduate students are intentionally designed to offer a hands-on experience like no other. Here, you’ll have the opportunity to sharpen your skills, collaborate with industry experts, and contribute to a new era of aerospace.

Growing With Relativity

Meet some of our former interns, now full-time team members.

Jonathan Williams

Stage Fluids Engineer I

I interned with the team I'm currently on, the stage fluids team, which is an awesome group of people. And it was great to already know most of them when I started full time! The projects that I owned during my internship were more focused on systems and analysis. I used Python and Excel to create tools that made our systems faster and easier to use. One cool thing I worked on was a leak check tool, which empowered technicians to finish leak checks and qualify hardware to the right standard. It was satisfying to come back after my internship and see people using the tool, I created in their PowerPoint slides for data analysis and referencing.

What made it a unique experience for me was the ownership and seat at the table I was given. I got to collaborate with top engineers who respected my opinions and work, and I truly felt like a valued part of the team.

Ty Teodori

Lead, Propulsion Design Engineer

I joined Relativity as an intern and had a great experience, so I decided to become a full-time employee. It's been over two years since then. In college I had the opportunity to do a couple of aerospace internships, which solidified my interest in the industry. This interest continued to grow when I joined Relativity as an intern and now as a full-time employee.

What made this internship stand out from previous ones was the immediate sense of being part of the team. The projects I worked on felt like real work, not just intern side projects. Unlike other internships where I felt isolated, at Relativity, my work was prominent and important.

Ingrid Shan

Factory Test Engineer I

My experience as an intern at Relativity was fantastic! My team trusted me with meaningful work that directly influenced the company's inaugural launch of Terran 1. Witnessing the impact of my contributions was truly empowering.

I was fortunate to have a supportive team that readily answered my questions and provided guidance, which greatly boosted my confidence. They treated me as a valued member, assigning me responsibilities comparable to a full-time employee. Due to this positive experience, I happily returned as full time member of the team!

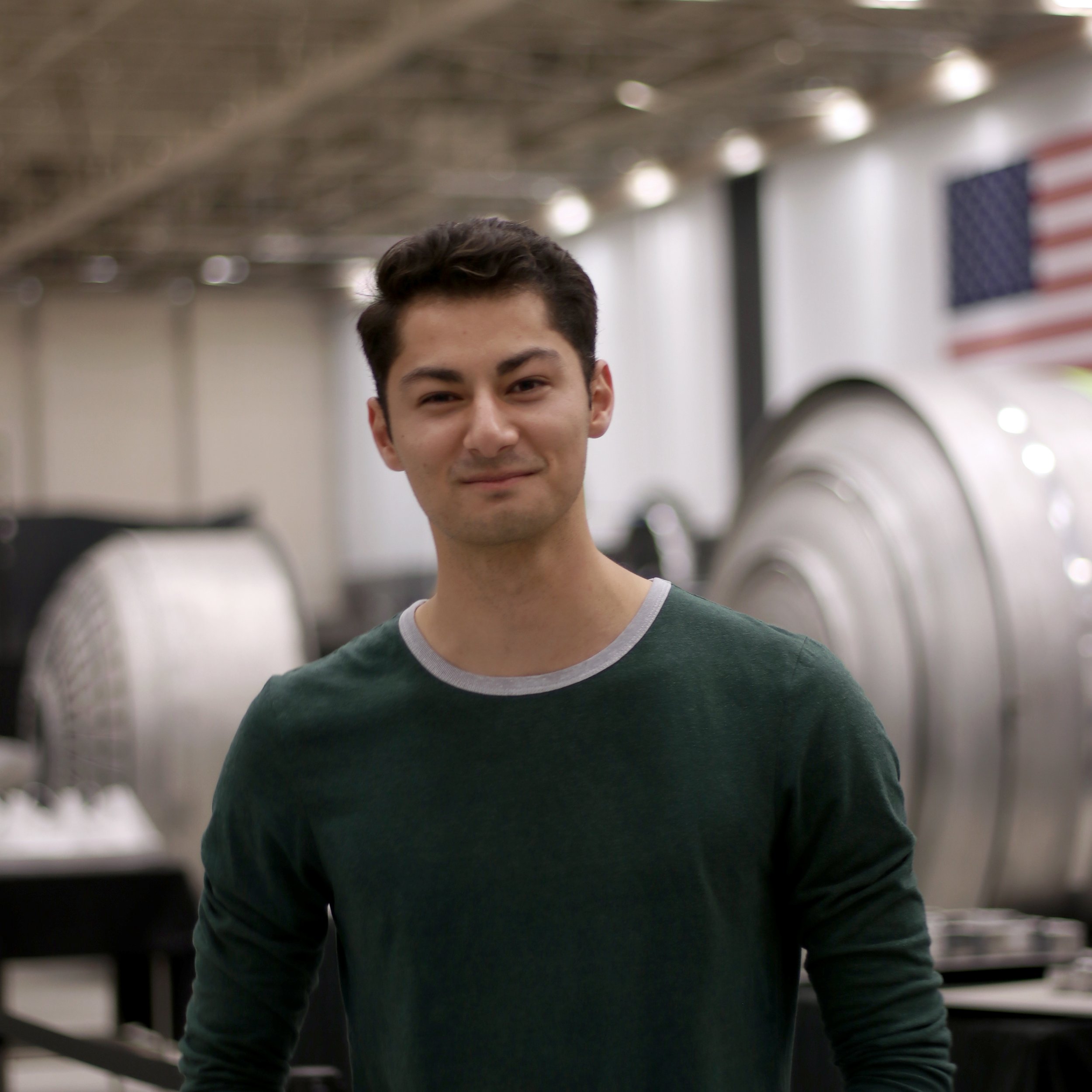

Konstantine Morakalis

Additive Development Engineer I

From intern to full-time team member, what's really cool is that we move fast here. We're not afraid to embrace new technology and keep pushing forward. And because we're still growing and developing, there's so much opportunity for ownership. I feel like I have a real impact, and my rate of learning here is way higher than anywhere else.

We have a concentration of brilliant minds, so if you want to learn something, the opportunity is right there. It's a place where things get done at a high pace and with high execution, and that's exactly the kind of environment I wanted to be in.

Join Our Team